Right...with powder coating all YOU do is remove any heavy grease / grime / oil /general filth.

It need not be perfect..just reasonably clean.

Powder coaters clean,mask threads and blind holes and then media blast or dip the item.

They do their own preparation so if there is contamination that ruins the finish it is their responsibility.

They do it right the first time so as to save expense. They do not trust final preparation by others

Your garage will not be coating but sending the part to a coater and adding their percentage to the cost.

Wheels will benefit from new bearings and seals anyhow...cheap as chips.

Very easy to refit...hard part is old bearing removal.

DO NOT skimp on bearing quality..the price difference on quality British , German or Japanese bearings versus Asian shite is the sum total of sweet fook all.....just a pound or so.

Warm up the wheel slightly with a heatgun/hairdryer and bearings out of a freezer in plastic bag virtually drop in.

You can drift them in with a large socket very easily too. Keep the bearings square...don't forget spacer tube.

Used replacement axle is readily available...its the thin locknut that is hard to source.

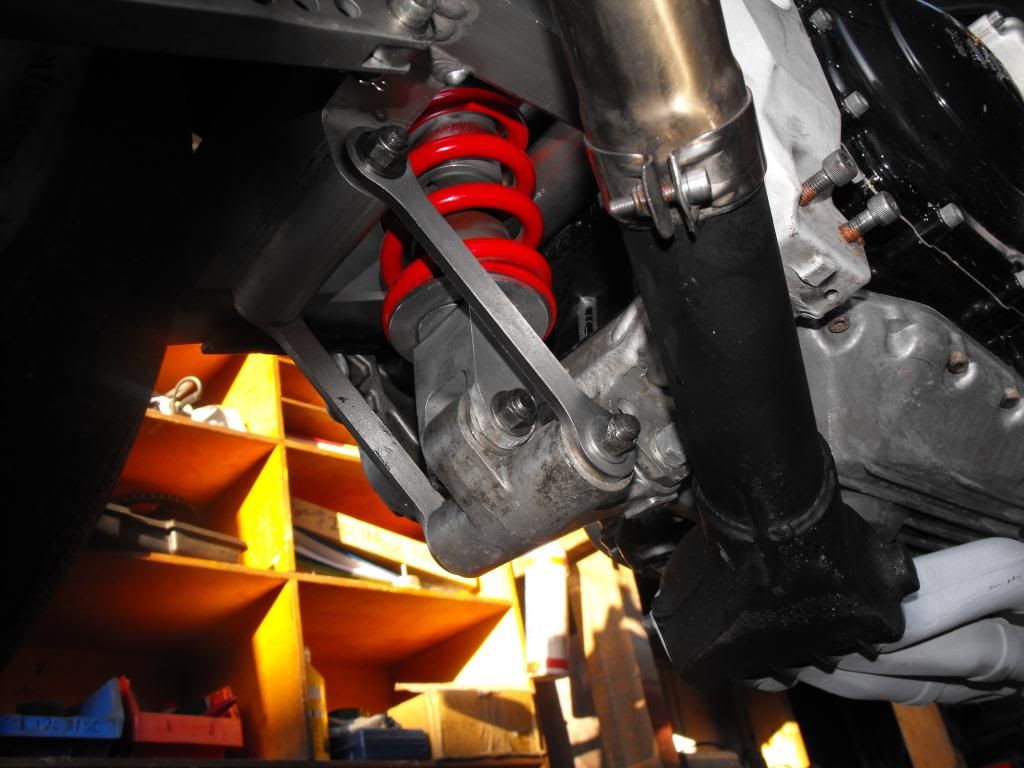

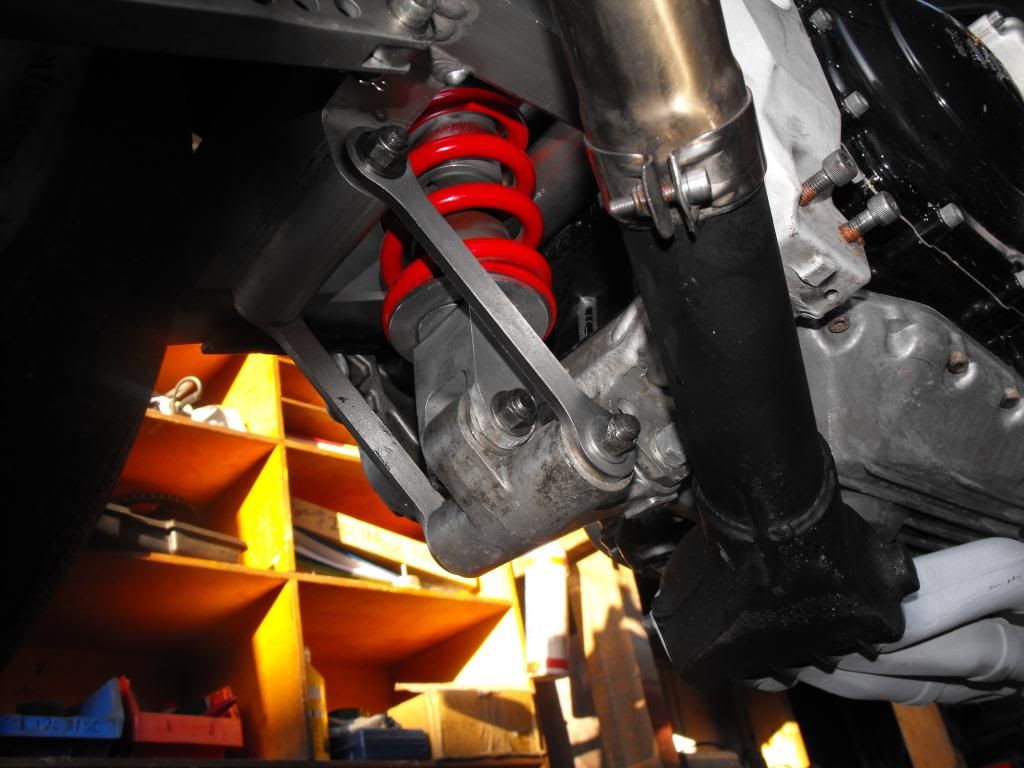

Standard upgrade for Genesis shock is Yamaha R6 2006 model shock with s/s replacement dogbones to compensate for slightly different shock lengths.

IIRC new dogbone hole centres are 138mm. Contact Kayla @ Projection Components."Stig" on here does them too.Both are UK vendors...Kayla probably does the small spacers if needed on the Genesis...(see link)

Google the mod. Its been done by thousands of owners now.

Cheapest shocks used to be German Ebay ..."Old stock takeoffs" circa £70 delivered to Uk...

Iv'e done loads of them....mint shock...far,far better than spongey old original which was made for lightweight Japanese riders even when new.

Pick the bones out of this.....

viewtopic.php?f=8&t=1134&st=0&sk=t&sd=a.

IF you had used a substantial drift AND the large nut when knocking axle out rather than direct blows to axle..you would have saved threads....it's a step learning curve sometimes but as stated prev. "The man who does no wrong ..does nothing " Lol.

You are strongly advised to remove the s/a pivot when you have the bike down this far.

Check all bearings and those of the shock linkage assy.

Most will be solid with rust unless you are very lucky.....

This is very easy to do when at the shock replacement stage.

Biggest grief is finding means to support m/c when the s/a is being removed....make sure spindles are loosened and slide freely BEFORE you concoct some means to support it temporarily.

ADDITION : UNDER NO CIRCUMSTANCES use generic fixings to replace any u/s items on the shock linkage..although they may fit, the correct bolts are CRITICAL on this assy... I cannot stress this too much.

Sent from my keyboard using the English language not some teen text shite from a fooking phone.