It made me grin to see the receipt for $500 worth of carb work. He had them cleaned and a few seals replaced is all. He didn't even know a carb sync was, but said he never heard the place that cleaned the carbs say it.

The bike started and idled fine when I took it for the first test drive. After driving it to the storage unit, it ran out of gas. The PO put seafoam in the tank, i'm assuming it was old gas he had in it. I put some new gas in it, and while it would idle fine it would stall as I tried to take off in first gear. After a few more tries, it would start for a few seconds (sounding like only one or two cylinders were firing) then stall. I'm assuming the old gas in the tank botched up the starter jet in the carbs explaining the takeoff issue, and my use of the choke fouled the plugs leading for the inability to run. If someone could comment on this, or explain to me the purpose of the damn choke, I would greatly appreciate it

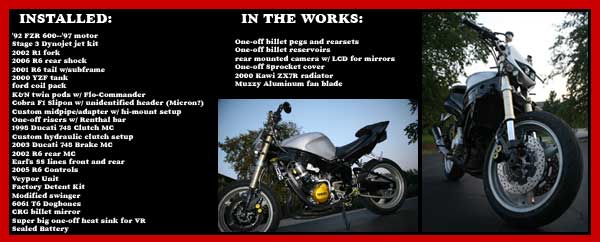

Here's what I got to help with this build:

Lincoln 180amp welder. Let me start by saying I SUCK at welding. I have not done much welding in my life, but when I have it was on 1/4 material typically, if not 3/8ths. I weld steel, never even attempted alum.

The machine was setup with a 75/25 mix of argon to CO2. .30 wire, attempted to maintain 3/8th inch stickout constantly using a forehand, or pushing, method of welding. The majority of time I did pulse welding because I kept blowing through the stock material (It surprised me how thin the frame metal was...) I still don't know what I was doing wrong. I tried turning up the penetration, AKA wire feed speed, as I was always able to do on the thicker material to prevent the blow through. I ended up doing my own version of pulse welding for the majority of the welds, which may explain why my welds suck.

check out my packing peanut wire cleaner. haha.

I started by making frame slider mounts. The idea came from Zero9243's rebuild thread (helped by ThatKid) on FZRonline forums. It's a really cool idea, kudos to those guys. Here's my version:

The mounts were made from scrap steel I had in the basement. I bought some welding bar from Lowes, cut it and welded it. I went through 3 Cobalt drill bits trying to get through them, using cutting oil. :wtf:

"Weld-thru primer"

prepare for crappy welding...

I burned through the frame so many times, it's not even funny. These are before I cleaned it up. Ugly as hell, but I KNOW I got damn good penetration.

I started working on the subframe then. I tried and tried to work with fiberglass, eventually got pissed and through all the fiberglass shit in the trash. Bought some 16g sheet metal and 1"x1" square steel with the same thickness of the subframe on the bike. cant recall what thickness, but it was thin. Unfortunately I didn't take pictures of building the point, but it's two pieces of this pipe welded to cut sheet metal. You'll understand when you see it.

This is the straight squared tube (I dont know what the hell to call it. but its not round. and I didn't know how to bend it without crushing it.) I bought. I cut a triangle out of one side, bent it to the correct angle, joined it by butt welds and grinded down the welds. you can see a few dark spots in the middle. those wouldn't be there if I was actually good at welding and knew how to do it without blowing through on this thin material.

Here's the bar welded to the stock subframe.

I'm missing photos again, sorry.

Here's the cutout of sheetmetal welded to the back of the point. This was my homemade version of pulse welding. It left some imperfections after I grinded it down... damn.

HORRIBLE WELDING:

This is a double pass of the sides for the rear seat. You can see a bit more of the point in this photo. The cutout on the right is where the rear seat latches onto. I used up a roll of wire, and shut of the gas when I installed the new one. Being an ass, I turned the machine on and started welding the sides on...without turning the gas on :doh: wouldn't have been a problem if I used innershield wire.

I ended up doing a double pass for a uniform look to cover up the pinholes. I end up grinding these out.

A lady friend came over with her nice camera to take pictures of my pups, so she shot a few of the bike aswell in its current ugly stance.

I wish I would have snapped a picture of it with the seats on, it looks sick.

Filled a few holes, the large frame cooler holes left a few imperfections after welding them shut and grinding it down, so I used bondo. which ended up showing through the paint a bit, big f*ck mistake on my part.

Figured I would see what I could do with this...

and hot rod flatz black. first time ever using paint not from a rattle can.

more pics to come, but I gotta finish painting a few imperfections. the engine is in flat black already using rattle can engine enamel I did a week or two ago, i'll grab pics of that here soon too.

I'm hoping after I touch it up it will look better.

started to work on the muffler some

hope the muffler works after I pack it...and shorten the downpipe with the correct angle.

stock muffler cutup