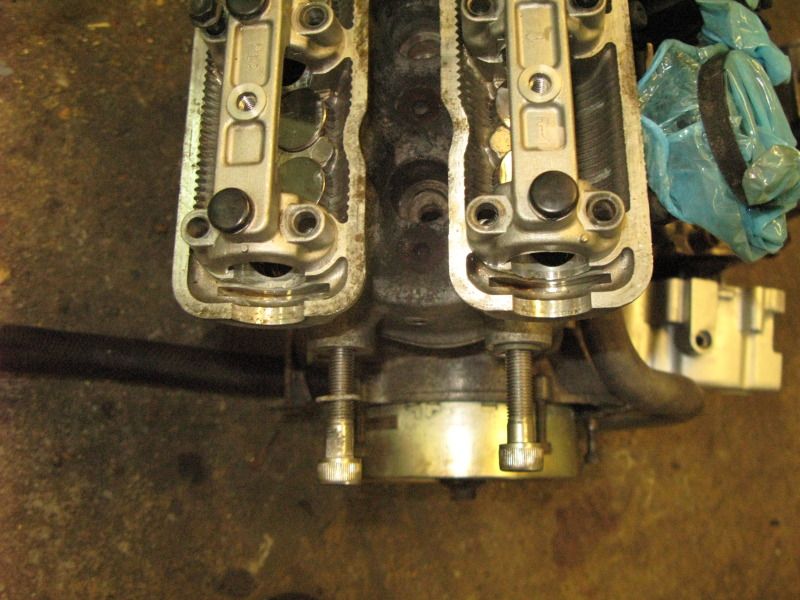

The shims are used to alter the valve clearance and there are many sizes.

The usual procedure is the bucket and the shim is bagged and tagged with location.

This makes for a much easier rebuild.

Each bucket is more than likely a different "height" and will have worn somewhat to the recess in the head.

Never mind, these things happen !

What you need to do is to reassemble the engine keeping note of shim location and size.

Keep the etched number face to the bucket so it is not worn away at a later date.

The shim size is pretty accurate.... a micrometer can be used to check if available.

When rebuilt, check the valve clearances.

There is a table in the manual.

Your going to find them all or most at least, out of spec.

Using your notes with your shim sizes and location and the spec table work out where you can swap shims to get the correct clearance.

You have to restrip the cams out and swap the shims....not the buckets though..rebuild and remeasure the clearances.

It will take a few attempts to get all the clearances correct again.

If you have stripped the valves out of the head and done work on either or the clearances were incorrect before you stripped the motor ..you will require additional shims.

Some old school shops have a shim swap programme if budget is tight.

If you have the cash ...buy an aftermarket shim kit.

They have 3x of each shim size...you will never use them all ...ever ...but it will save numerous cams in/out/measuring.swapping/remeasuring......rinse and repeat.

http://www.ebay.co.uk/itm/Hotcams-Valve ... 2a50fb33dc

As always ; do an update.

If you pull it all apart and get the valve clearances spot on at the first attempt....go straight out and buy a lottery ticket.

Send half of the money you win to me !