Custom Headlight Evolution (Loads of Pictures!)

Posted: Sun Dec 04, 2011 12:45 am

So I believe that a headlight sets your build. It can make or break all your hard work. If you are building something unique no off the shelf headlight is going to cut it. Headlights have always been my kryptonite.

It took a very long time for this one to take shape.

The design came one day while I was messing around in the shop. I was looking at some remnant pieces of aluminum I had lying about and something finally clicked. The Hella projector that I had purchased for an airtech kit was laying on the shop table next to the aluminum.

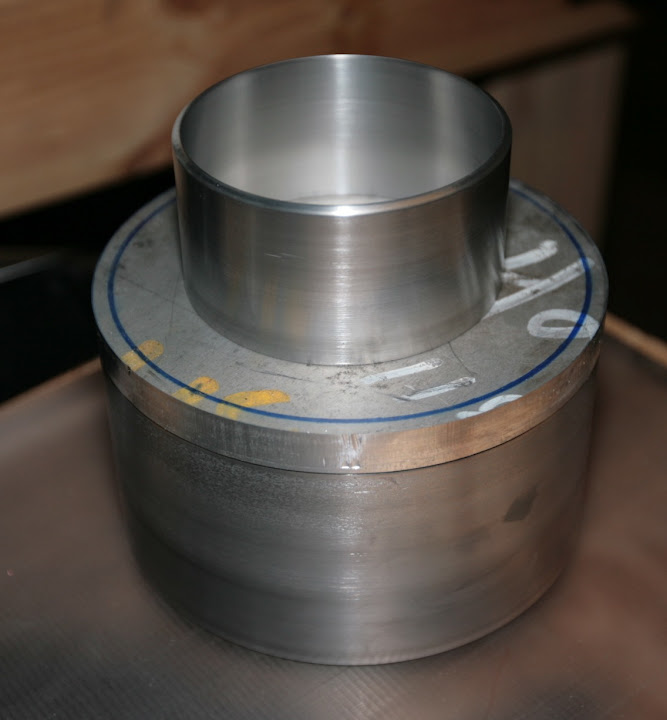

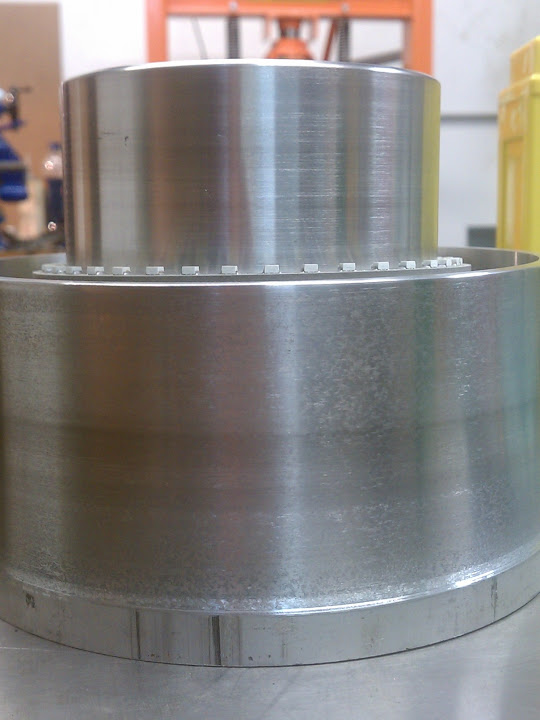

First I needed something that would hide the ugliness of the projector housing.

Then I started to play.

Things were looking alright as far as fit went for some random bits laying about.

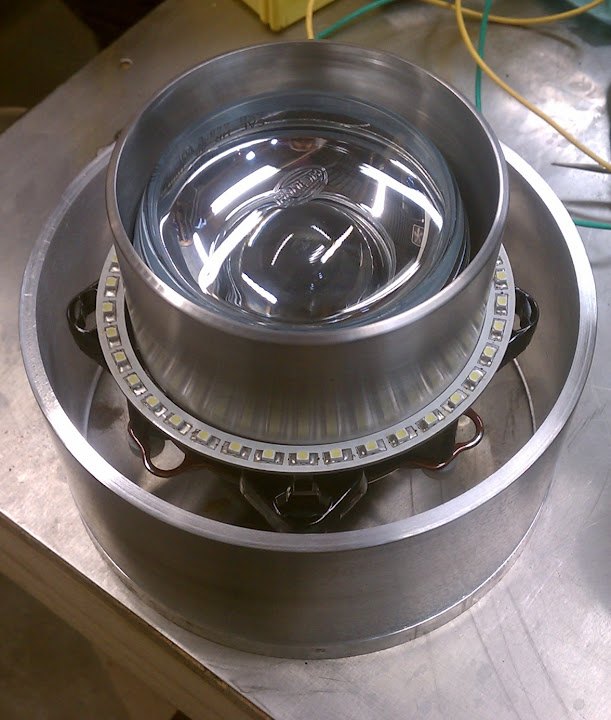

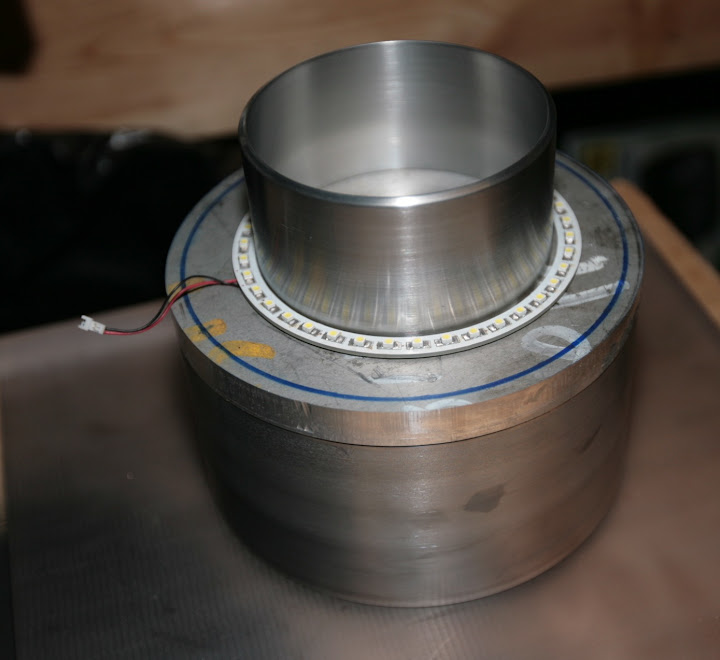

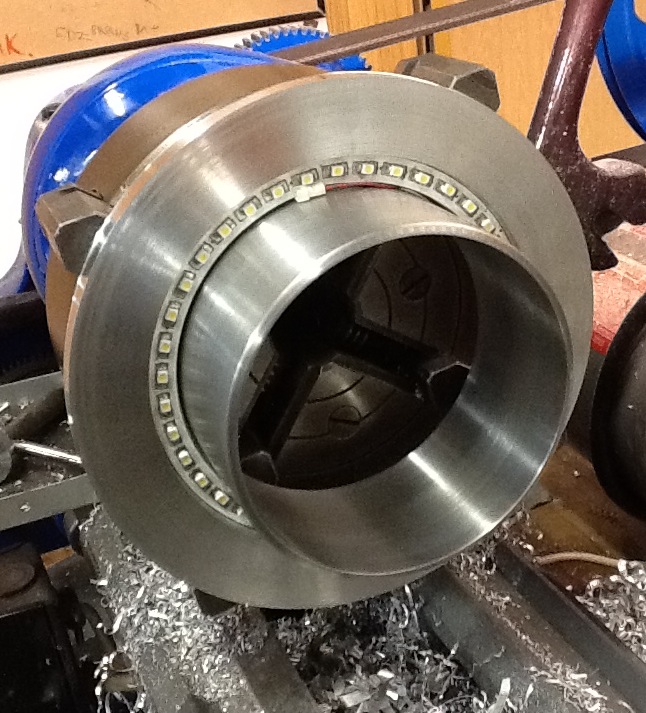

Why not add a halo?

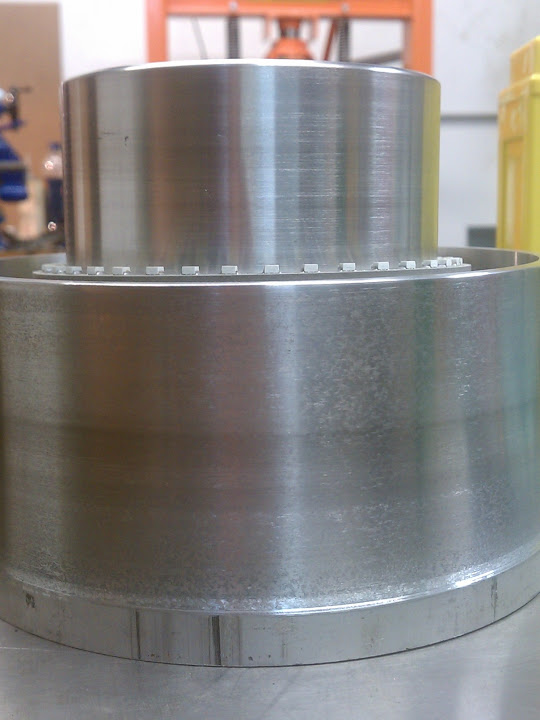

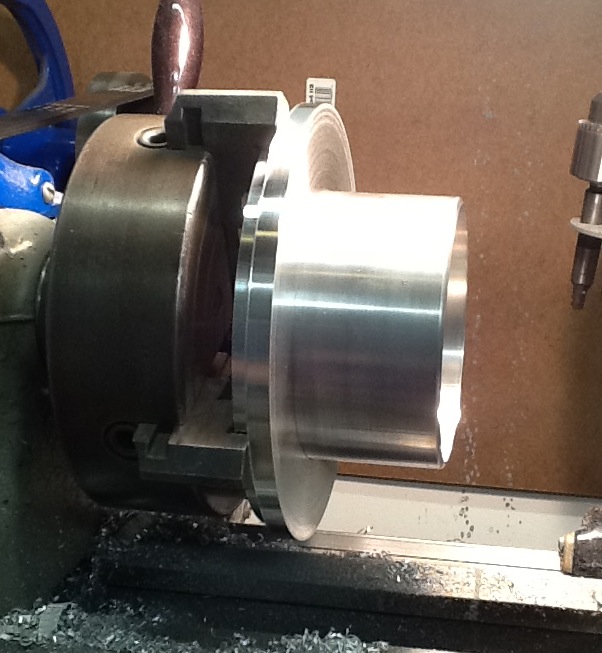

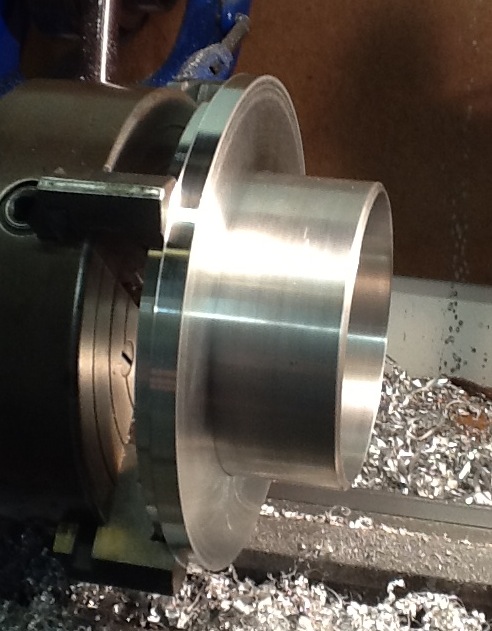

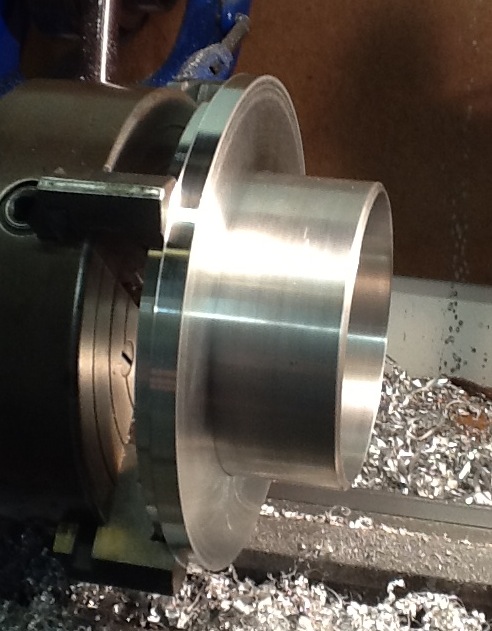

Then work picked up and the headlight idea sat for a month or so. When I got some free time I turned down the aluminum a bit and polished it up a bit.

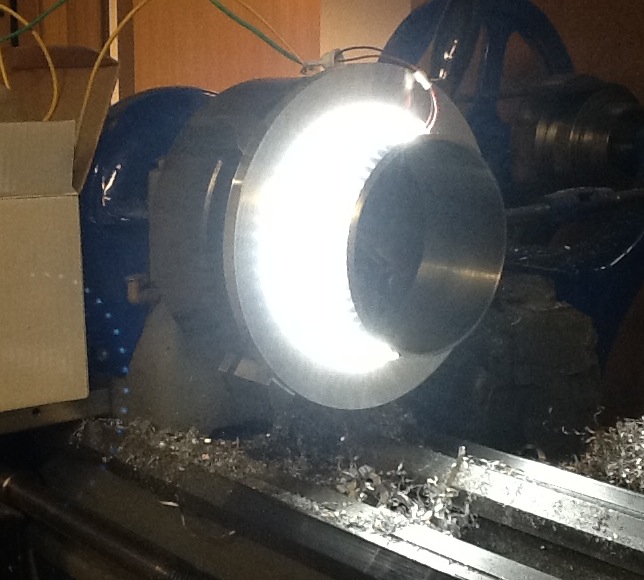

With the polished surface the halo reflects pretty slick like in the dark.

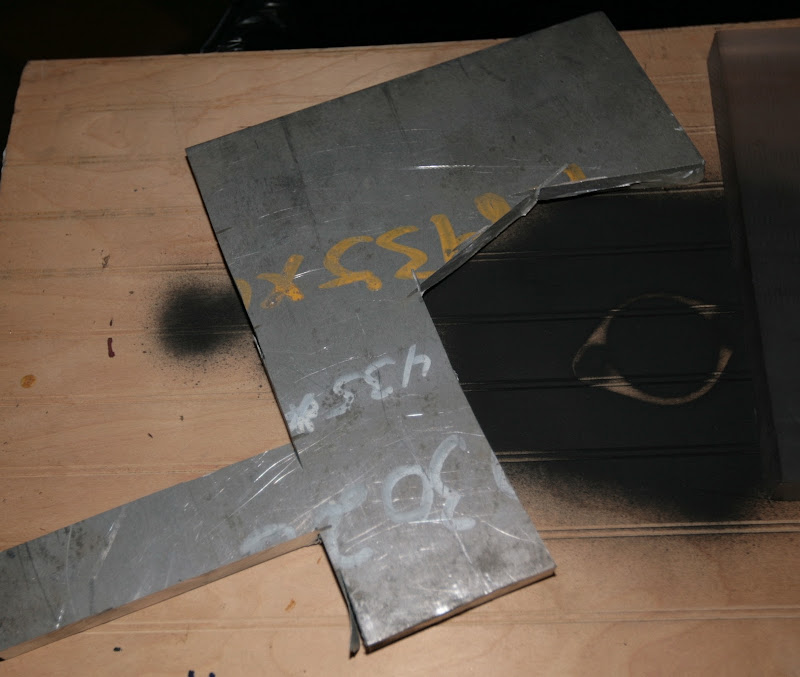

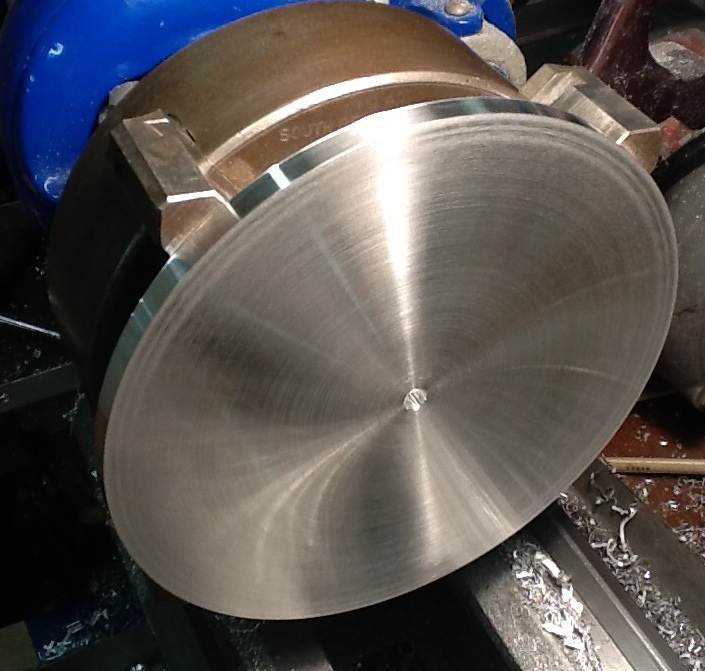

And again I stopped due to work. I also wasn't sure what I was going to make the front out of. Plastic or acrylic would have been the easy choice and I did have some lying around. However, I couldn't start half-assing it now. Welcome to one hellish time. First I used an angle grinder with a cutting disc to cut out a squarish area. Then I clamped that to the rotary table and milled away.

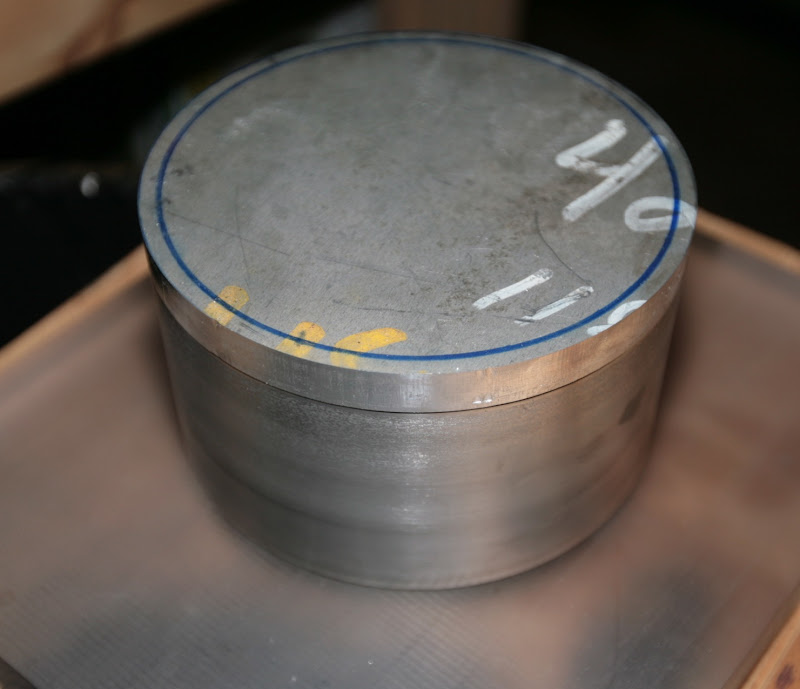

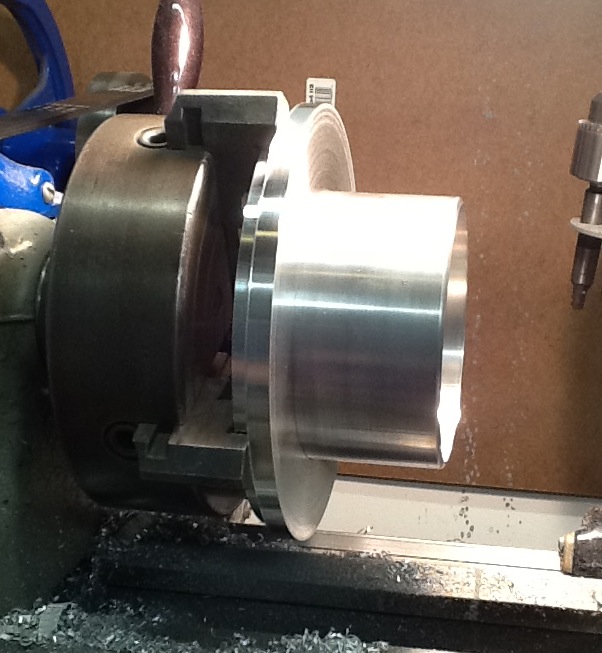

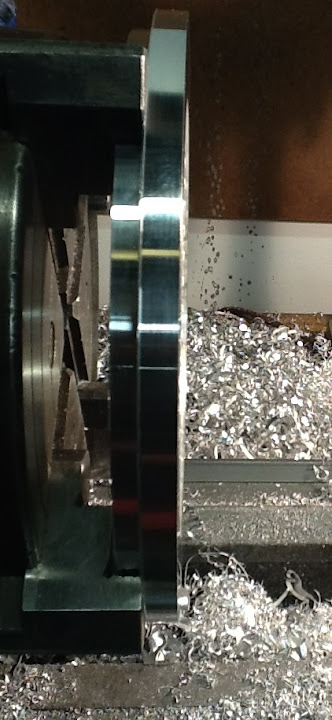

I have just enough overhand to turn it smooth on the lathe and still line up with the main body.

More stacking to see how it will look.

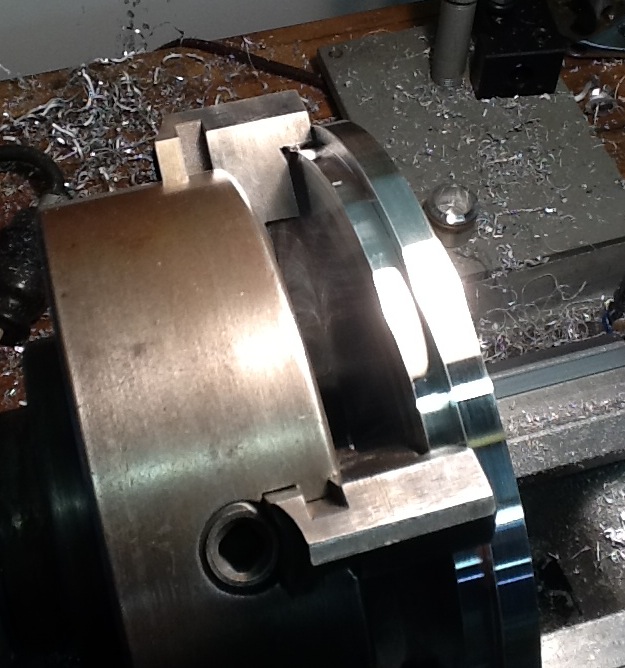

And now the precision work begins. I need very tight tolerances in order for everything to be a nice press fit. It will be secured somehow, but I'm not sure just yet on how that will be.

Cleaning up the front and sides. I cut the groove for it to slide into the main body.

The first bit of the circle. Not even an 1/8" deep yet.

And my tolerances are agreeable. Front surround holds on.

Got the hole all the way through except for a small lip on the back to use as a stop.

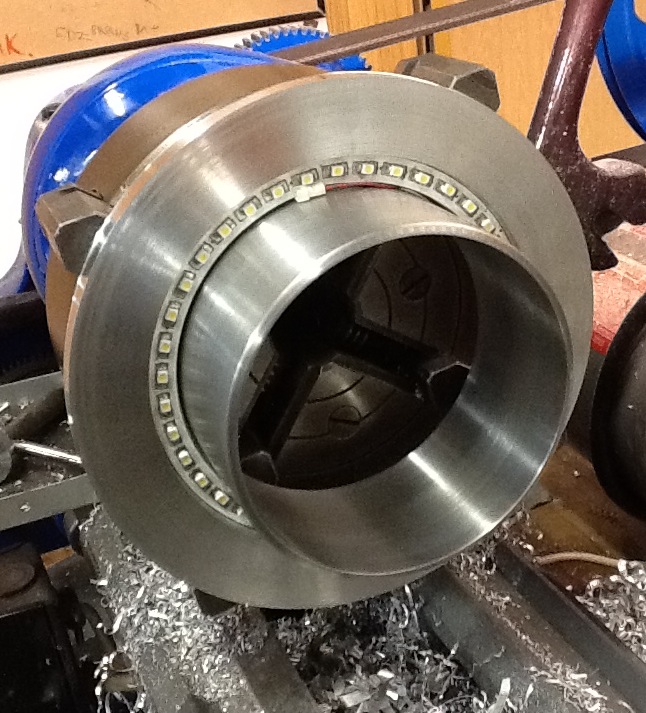

Next up was to get a groove for the halo so it would be recessed.

Done and done!

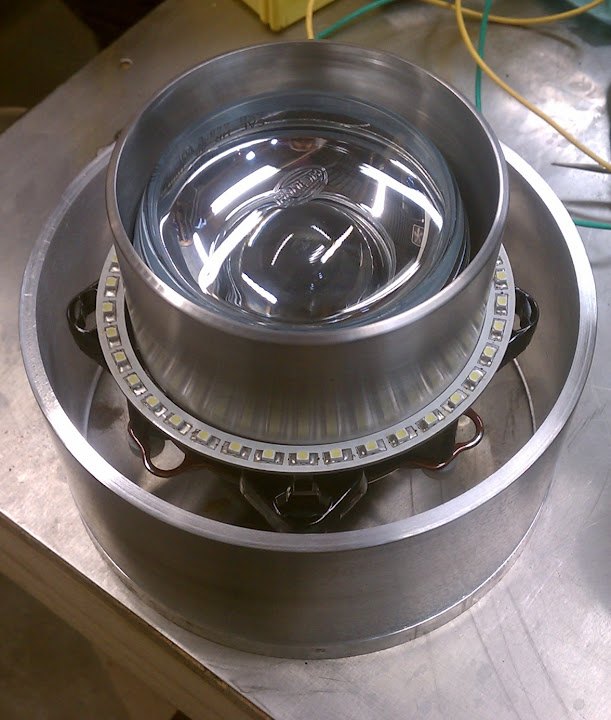

Everything back together for a test fit.

And well, why now power it up?

Next on the agenda is adding the turn indicators somewhere. I was thinking on the face and possibly on the mounts for the whole assembly, but that's for another day.

It took a very long time for this one to take shape.

The design came one day while I was messing around in the shop. I was looking at some remnant pieces of aluminum I had lying about and something finally clicked. The Hella projector that I had purchased for an airtech kit was laying on the shop table next to the aluminum.

First I needed something that would hide the ugliness of the projector housing.

Then I started to play.

Things were looking alright as far as fit went for some random bits laying about.

Why not add a halo?

Then work picked up and the headlight idea sat for a month or so. When I got some free time I turned down the aluminum a bit and polished it up a bit.

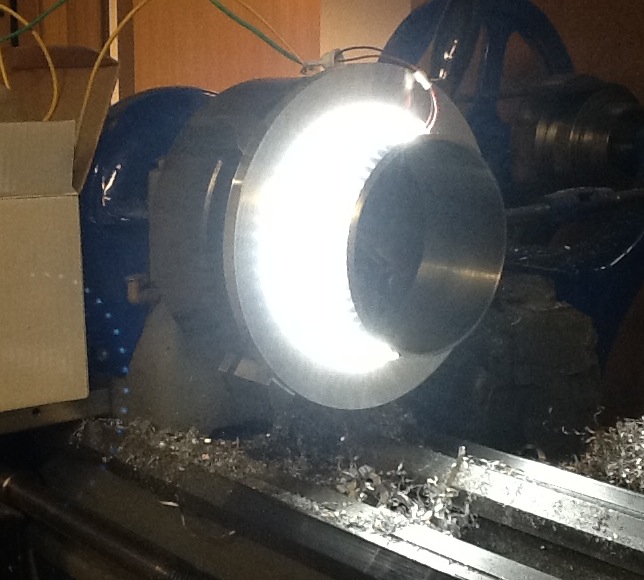

With the polished surface the halo reflects pretty slick like in the dark.

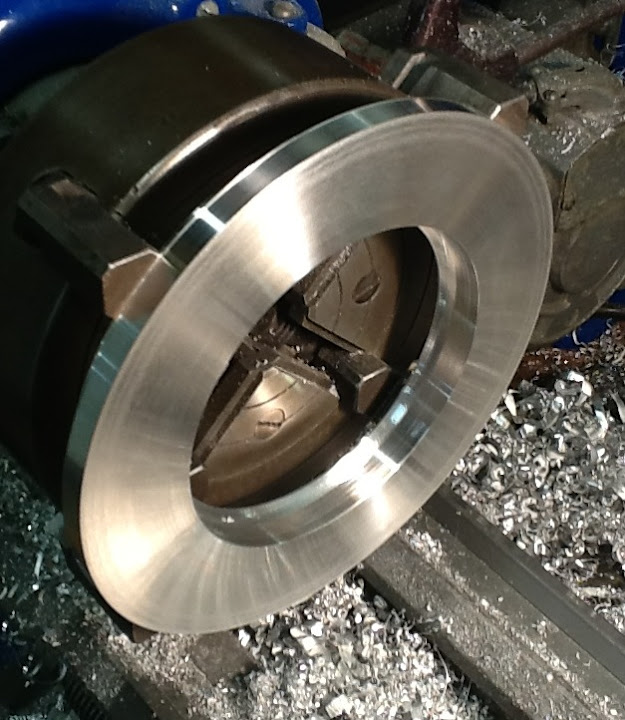

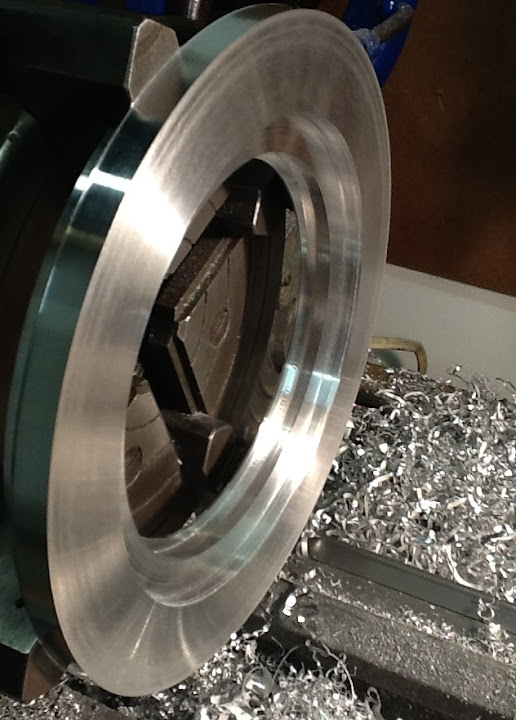

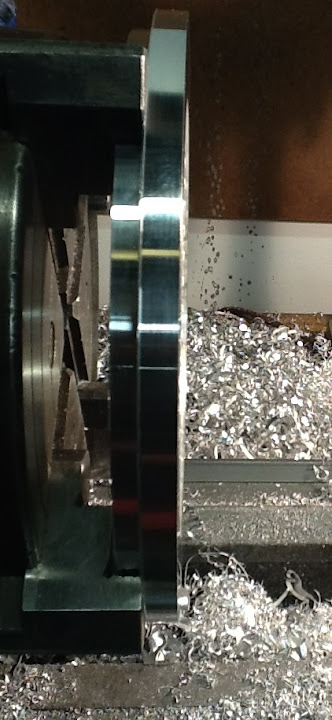

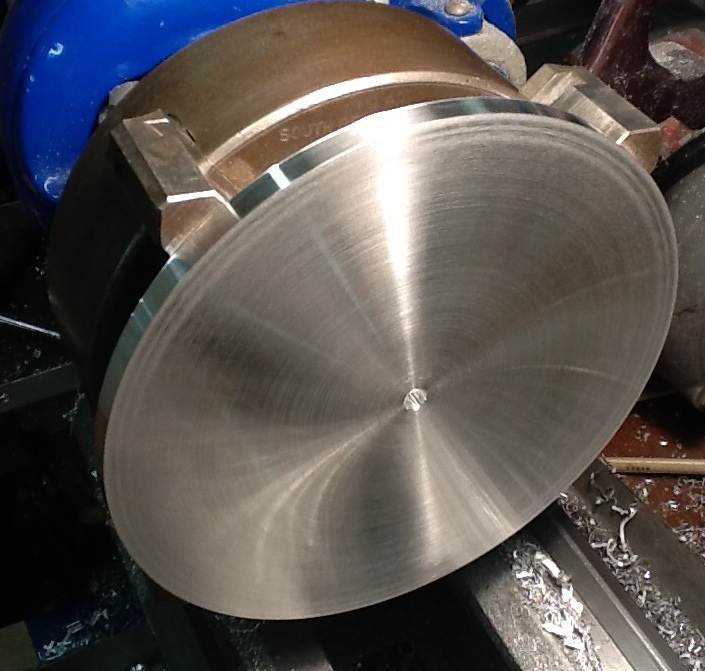

And again I stopped due to work. I also wasn't sure what I was going to make the front out of. Plastic or acrylic would have been the easy choice and I did have some lying around. However, I couldn't start half-assing it now. Welcome to one hellish time. First I used an angle grinder with a cutting disc to cut out a squarish area. Then I clamped that to the rotary table and milled away.

I have just enough overhand to turn it smooth on the lathe and still line up with the main body.

More stacking to see how it will look.

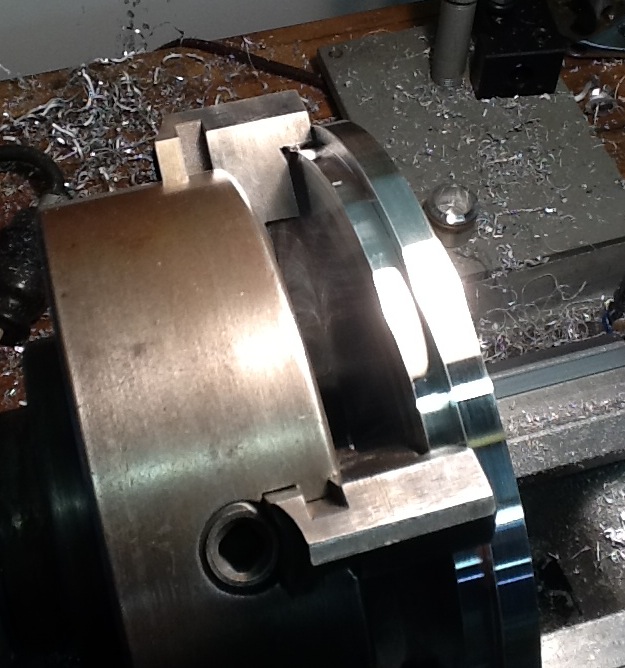

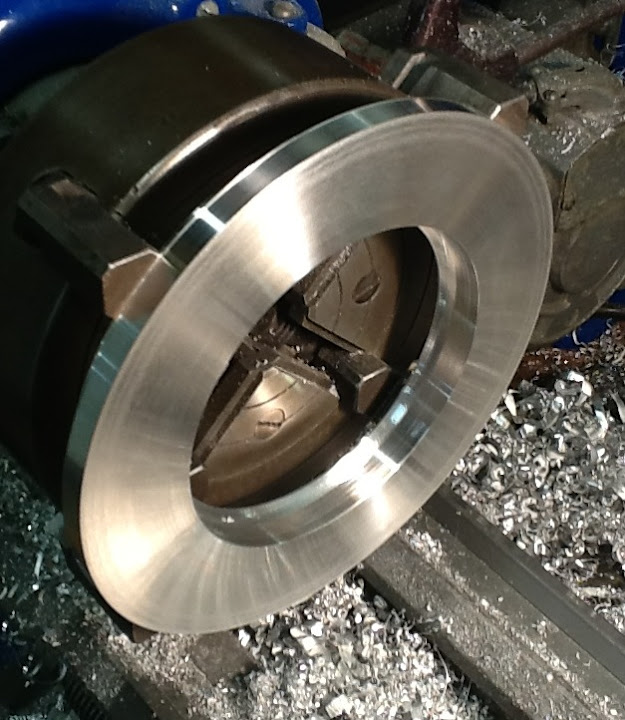

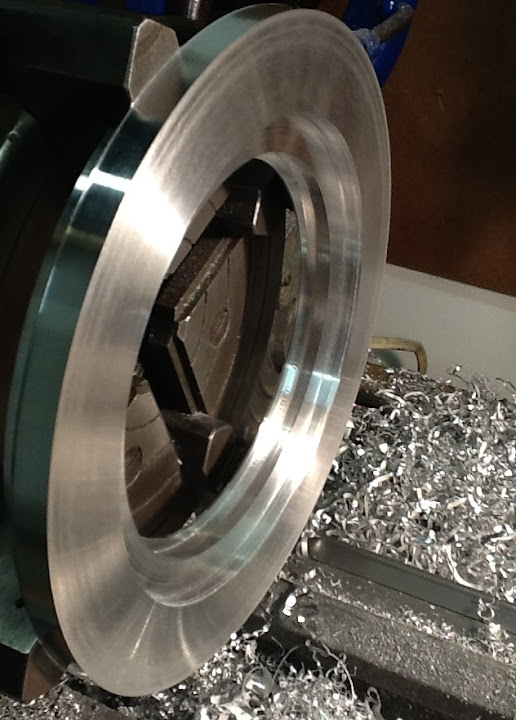

And now the precision work begins. I need very tight tolerances in order for everything to be a nice press fit. It will be secured somehow, but I'm not sure just yet on how that will be.

Cleaning up the front and sides. I cut the groove for it to slide into the main body.

The first bit of the circle. Not even an 1/8" deep yet.

And my tolerances are agreeable. Front surround holds on.

Got the hole all the way through except for a small lip on the back to use as a stop.

Next up was to get a groove for the halo so it would be recessed.

Done and done!

Everything back together for a test fit.

And well, why now power it up?

Next on the agenda is adding the turn indicators somewhere. I was thinking on the face and possibly on the mounts for the whole assembly, but that's for another day.