Page 1 of 1

Total loss rotor

Posted: Fri Jan 02, 2009 3:00 am

by dru86

The stock flywheel weighs 1.6kg which is weight I would like to loose for trackdays and since the factorypro total loss rotor is $180 I've decided to make my own. I'm basically going to machine the rotor down to the red circle then machine in the pickup lugs. I'm facing abit of a dilemma atm as I'm not sure whether to mill in the lobes at the same stop/start degrees, which is what can be seen marked on the rotor (this will shorten the length of the lobes, but not the exposure time to the pickup) or to have them start at the same point however be the same length as the original lobes so would have a later stop point. From the pictures I've found of total loss rotors It's hard to tell. I'm inclined to think that I'll leave them at the same stop start degrees.

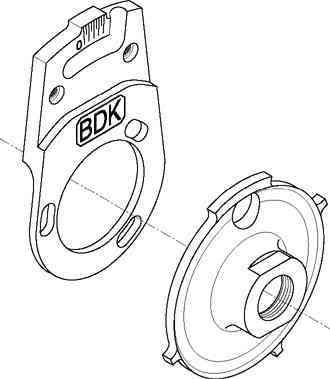

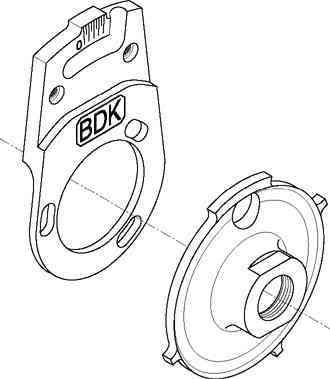

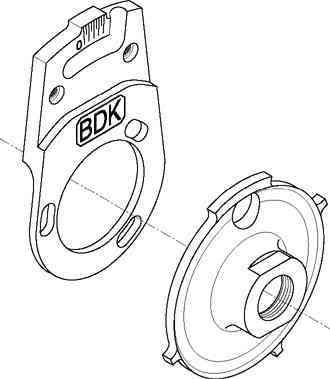

Factorypro flywheel

BDK flywheel

home made flywheel

Re: Total loss rotor

Posted: Fri Jan 02, 2009 3:12 am

by shredex

there is a battery you can get for bikes which allows you to completly remove your flywheel/stator...

it also is about the size of a wallet and weighs alot less than a stock battery and produces more juice also...

but its f**king expensive...

Re: Total loss rotor

Posted: Fri Jan 02, 2009 8:04 am

by yamaha_george

dru86 wrote:The stock flywheel weighs 1.6kg which is weight I would like to loose for trackdays and since the factorypro total loss rotor is $180 I've decided to make my own. I'm basically going to machine the rotor down to the red circle then machine in the pickup lugs. I'm facing abit of a dilemma atm as I'm not sure whether to mill in the lobes at the same stop/start degrees, which is what can be seen marked on the rotor (this will shorten the length of the lobes, but not the exposure time to the pickup) or to have them start at the same point however be the same length as the original lobes so would have a later stop point. From the pictures I've found of total loss rotors It's hard to tell. I'm inclined to think that I'll leave them at the same stop start degrees.

home made flywheel

Whilst removing weight is always good, there is also a problem with too little weight to even out the power "pulses" of the engine firing, this is particularly noticeable in corners at the race track when you slam the throttle closed and turn and then throw the bike upright & nailing the throttle.

The inertia of the flywheel is no longer there to help slow the slowing process and is not there to help the start of going to higher revs.

Re: Total loss rotor

Posted: Fri Jan 02, 2009 10:46 am

by reelrazor

Like George, I think there are ramifications to consider beyond just shedding rotating weight. The vast majority of the load is taken at the right of the crank and the flywheel is at the left. Crank twisting occurs dynamically with forged cranks in small-blocks w/o proper harmonic balancing. Two stroke watercraft and sled engines are notorious for cylinders closest to the load going into excessive ign. advance under load(lagging behind the ign trigger).

falicon or someone else like them can probably eliminate as much weight w/o affecting overall crank balance(end to end as well as radially)

But, if you have your heart set on this, my first thinking is that if you decrease the diameter of the flywheel and move the pickup coil closer as shown in the pics is that you need to decrease the length of the rotor bumps to have the same effective arc/degree (time)under the pickup.

Are you converting the ign. to single spark as shown? If so, I would consult the ign. controller manu to see what their arc/degree parameters are (and what that needs to be for the 'counter' position bump).

Re: Total loss rotor

Posted: Tue Jan 06, 2009 1:46 pm

by yamaha_george

dru86 wrote:The stock flywheel weighs 1.6kg which is weight I would like to loose for trackdays and since the factorypro total loss rotor is $180 I've decided to make my own. I'm basically going to machine the rotor down to the red circle then machine in the pickup lugs. I'm facing abit of a dilemma atm as I'm not sure whether to mill in the lobes at the same stop/start degrees, which is what can be seen marked on the rotor (this will shorten the length of the lobes, but not the exposure time to the pickup) or to have them start at the same point however be the same length as the original lobes so would have a later stop point. From the pictures I've found of total loss rotors It's hard to tell. I'm inclined to think that I'll leave them at the same stop start degrees.

Dru,

You may like to keep the flywheel just skimmed down and use one of these :-

> http://www.gybe.eu/files_project/5/PDF_1.pdf

YES they are looking for dealers in the US !!!!

For now you can buy at Rally Bike Center in Zetten Holland

Tel nr +31 (0)488453424

Their website is off line @ the moment

As far as i know this battery can be used with the bikes normal charging

system

Re: Total loss rotor

Posted: Tue Jan 06, 2009 6:36 pm

by megaloxana

shredex wrote:there is a battery you can get for bikes which allows you to completly remove your flywheel/stator...

it also is about the size of a wallet and weighs alot less than a stock battery and produces more juice also...

but its f**king expensive...

you still need the pick-ups for the ignition.