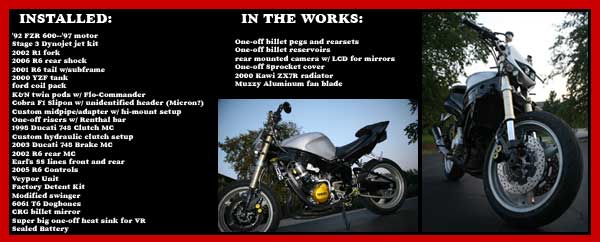

Here is the installation process for my hydraulic clutch conversion using Modking's adapter kit. As always, the workmanship is fantastic, otherwise I woudlnt keep bugging him to do work for me. Included in the kit is the slave cylinder mount, 2 bolt spacers, and a new pushrod tip.

I did not want to have to take anything off my bike prior to the installation so that I could continue to ride while I waited on parts. This really meant that I needed to get a new clutch pushrod so I could modify it first and then just swap it with my existing one when I install the new stuff. So a few days ago I picked up a new pushrod from a local yard. Its a 3 piece rod, aluminum rod, with 2 hardened steel end. One is just a nub, the other is about 3" long and has a narrow tip. This one has to come off. Clamp the pushrod in a vise with 2 pieces of wood and apply heat with a torch to the aluminum near the long tip. Careful not to overheat, it doesnt take much. Clamp onto the tip with a pair of vise grips and twist and pull until it comes off.

Once it is out, apply more heat to the aluminum rod and push the new tip in as far as it will go. Take the rod out and put the new tip down on the workbench and lightly tap the pushrod with a hammer until the tip is fully engage. No gorilla smashes here! Modking suggested using a piece of angle iron to align everything while hammering. I didnt have any angle, so I screwed the 2 scraps together that I used to hold it in the vise to make a V, but didnt really need it. I used a friends torch but didnt have it to put everything back together, so I used the gas range in my kitchen and stuck the tip in the freezer for a few hours. It slipped about 90% of the way in for me and a few good taps and it was seated.

Now that the pushrod is done and all the parts are here, I can begin the install.

First, I removed the stock clutch lever and perch from the handlebar. Then I removed the sprocket cover and pulled the cable through the bike and set it aside. I really liked my red sprocket cover and I am sorry to see it go. It gave a nice splash of color to the black. Oh well, function over fashion. Now is a good time to clean all the funk out of there. Its surprising how fast this gunk builds up.

Remove the stock clutch pushrod by pulling it straight out. Stand the bike upright while removing the pushrod as oil will want to come out the hole. Install the new one quickly to minimize oil loss.

Next, install the slave mount. There are 2 bolt spacers, a short and a small. Short goes at the top, the long one goes at the bottom. This is where I encountered my first major problem. I forgot to mention that I was running a YZF swingarm and that my front sprocket is offset 8mm outward. With the included spacers, the bracket hit my chain and was nowhere near close to fitting. After taking a break and coming back later more clearheaded, I was able to find a simple method to space it out the necessary distance. I went to Ace and bought a handful of different parts for different ideas. The simplest was the one I chose and it seems to work out OK so far. I used M6x50 screws as well as some shorter ones for the water pump from my hardware bin. I put a hex nut and a jam nut threaded together onto the ends of the screws after the included spacers top and bottom. Or in the case of the 2 bolts that replace the water pump cover bolts, the nuts go between the slave mount and the pump cover. One of the screws for the water pump cover needs to be a full thread screw, and not partial like most M6 screws. The buts have to go all the way down to the backside of the cover so it will sit between the pump cover and bracket. The nuts I have thickness worked out perfectly. The jam nut plus the hex nut=8mm thickness. This way, I did not have to be so precise trying to make new longer spacers, and could evenly space the whole bracket outward easily. I have about 2mm of clearance now with my chain. Its close, but it should work. I dont think I will be able to go up to the 15 tooth front sprocket that I wanted to though, unless I space the thinkg out more. I still might take it back off and shave it down near the sprocket. Its damn close.

The kit includes a new tip for the pushrod that is longer, and it should be the right length for a normal FZR, but on mine, since I spaced it out more, I need to compensate for it at the pushrod. A ball bearing is the common method and I happened to have a few upper stem bearings from some USD front ends that dont fit anything and I have no use for, until now. They use 8mm roller balls, so I grabbed one and popped it in the slave. Theyre also available at Ace. I also applied a healthy dab of grease to the bearing before dropping it in the salve cylinder.

I didnt realize until I got the kit that the Ducati slave cylinder needs the little ears on ends of the mounting face ground off to fit in the bracket. Not a big deal to do, just a few minutes with the grinder. But if I had known prior, I would have sent the good slave off at first instead of the spare one. Once I get motivated one day, Ill grind down and repaint the nice one so it fits.

Now its time to install your clutch master cylinder of choice. I opted for a Brembo radial unit off of an 07 Aprilia RSV1000. After a few coats of paint, its ready to go on my bike. You will need to fab up some sort of bracket to bolt the resrvoir down depending on the type of MC you use. Luckily, mine came with the stock bracket. It wont take much to mount it for me, I just need to drill and tap a small hole on the bar. Not having a clutch cable really cleans the front end up.

Route the hose through the bike. I used a stock Ducati SS clutch line. I think it is for a Monster. There are 2 different kinds of hoses that I have seen, one has almost straight banjo bolts, and one has 90* banjo at the MC. I used the kind with the 90* bend, but I flipped it around and used the 90 at the slave, not the MC, it allows for a much better fitment. Frankly, I couldnt have made it fit the other way. So if youre buying a new hose, I recommend looking for the one with one bent banjo.

Fill the slave cylinder with fluid to the top first and then install the hose and banjo bolt. Then install the slave cylinder onto the mount, over the pushrod. This should push fluid back up into the line so no bubbles are caught in the slave while bleeding. It should make things a little easier. But the components I used, the radial MC especially, make it really easy to bleed.

Fill the reservoir and bleed the system.

After I got everything bled and tested the clutch function with the bike off, it seems to be in proper working order. The lever feel is very soft. The only issue I am having is a lot of free play in the lever before the clutch disengages and is probably a result of spacing it outward. I think I need to add another ball bearing inside the slave, but that might be too much. Im still weighing options on this one. As it is now, so long as I leave my lever on the top 2 or 3 settings its ok, otherwise it hits the bar before the clutch disengages fully. It might be just be that it feels so soft, there is very little resistance to the lever. But my bike decided to die on me yesterday and I am working on the carbs tmrw, so I cannot test ride just yet, or even fire it up and test it out in the yard. Its very angry with me right now, but I think I know why. I blame warm weather in winter.

After I ride on it a bit, I will give some feedback on the setup. I still need to pick up a clutch switch for this MC. Right now I have the connectors jumpered together, so until I get one Ill have to be mindful not to start the bike in gear without my hand on the clutch. I am going to stop by an Aprilia/Ducati dealer once the bike is running again and see if they have one in stock.

Lots of credit to Modking who did great work and hooked me up big. I can always count on his work and cannot recomend strongly enough to someone looking to do this mod. MK is the man to talk to. His hard work has taken all the guess work out of this project. Unfortunately, I dropped the ball a little and forgot to mention my sprocket setup, but since when was anything easy on my bike? I will probably need to make a few more small adjustments here and there to get it exactly how I want, and I will be sure to include any changes I make. For the avaerage FZR owner, this should be a much simpler process than mine was. I ran into a lot of issues and if I had to go through the same again, Id think twice, but I think it will be a good mod, and should help with the stress on my left wrist. Plus it really cleans up the front end. Not having that clutch cable helps me a lot. It would push down on my headlight whenever I turned and move it around. Plus, with stock routing and low R1 clipons, it had a pretty tight bend to it. The adjuster was a pain in the ass, and when I removed it I found my 1000mi old cable was already fraying inside it. Now I just need to get some damn shorter throttle cables and maybe bring the light up a hair and Ill be all set up top.